In a bias-ply tire, the threads of the carcass lie at a 45° angle to the direction of travel. This is the standard construction method for bicycle tires. In radial tires, on the other hand, the threads lie at a 90° angle, but require a so-called belt under the tread. Schwalbe radial tires have a much more obtuse angle than conventional cross-ply tires, but do not require a belt.

Is it possible to develop flexible tires with maximum utilization of the contact area that offer even more grip, control and comfort?

Yes, it is!

RADIAL REVOLUTION: REDEFINING MOUNTAIN BIKE TIRES

The latest development from the Schwalbe LAB: With the innovative radial tire technology two new MTB tires are coming onto the market. The basis for this new technology is the completely rethought carcass construction.

More grip

for even more control

More comfort

thanks to more cushioning

Larger contact surface

on the ground

THE ADVANTAGES OF RADIAL

Carcass threads at a more obtuse angle than other tires

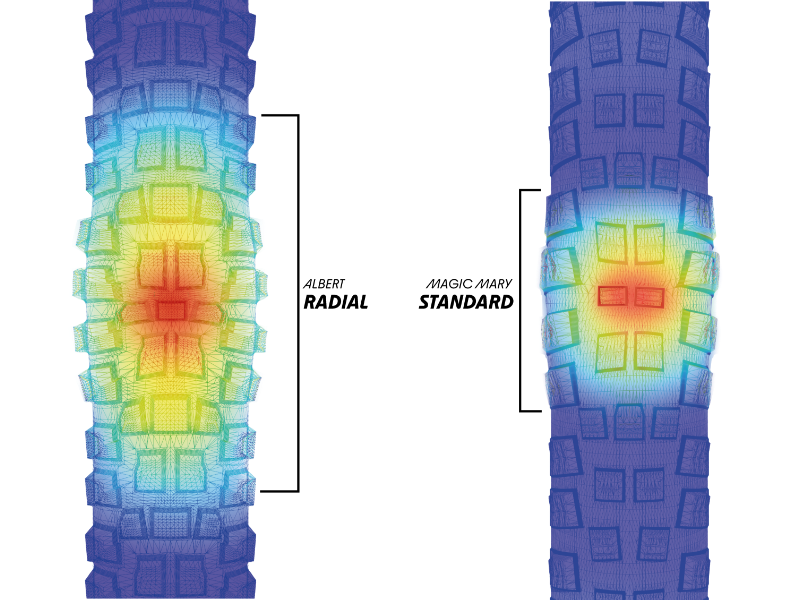

30% more contact area with the same air pressure

More grip, more damping, more control

WHAT DOES RADIAL MEAN?

The basis for this is the completely rethought construction of the carcass. The carcass threads, which run diagonally across the tire at a 45° angle in conventional bicycle tires, are arranged at a much more obtuse angle in our radial tires. This technology opens up a completely new dimension in the function of bicycle tires.

HOW RADIAL TIRES WORK

THE NEW PRODUCTS

The new radial tires come in three new profiles: Albert, Shredda (Front / Rear) and Magic Mary Radial.

FREQUENTLY ASKED QUESTIONS ABOUT RADIAL TIRES

Due to the blunter angle of the carcass threads, the tire can deform more selectively. As a result, it follows bumps many times better than a bias-ply tire and always maintains contact with the ground. The result: more grip, more comfort and more control off-road. In addition, the contact area increases by approx. 30% with the same air pressure.

Due to the larger contact area with the ground, Schwalbe radial tires always have more rubber in contact with the ground. As a result, rolling resistance increases slightly. However, this can be almost compensated for by clever tread designs, as already demonstrated on the ALBERT, for example.

This is intentional and is due to the higher number of weft threads in the carcass as a result of the blunter carcass angle. Weft threads are necessary in the production of tire carcasses to facilitate processing in production through to assembly. After fitting, these naturally break-in during riding.

Although Schwalbe radial tires are considerably more flexible under the tread, they behave almost identically to cross-ply tires in terms of lateral stiffness. This means that they can fully exploit their advantages on uneven surfaces, but do not become more unstable due to our special carcass construction.

We recommend initially using the same air pressure as a cross-ply tire with a comparable carcass construction (e.g. Gravity or Super Gravity). However, since Schwalbe radial tires are more flexible than conventional cross-ply tires even at higher pressures and retain their positive characteristics, the air pressure can be adapted much better to the riding conditions. For example, if the track conditions require a higher pressure to prevent punctures, this is easily possible with Schwalbe radial tires without having to accept disproportionately large compromises in grip.

Since we have only adjusted the angle of the carcass threads, but not the number of carcass plies or the material thickness, Schwalbe radial tires are no more susceptible to punctures than bias ply tires. The cut and puncture protection therefore remains positive.

.png)

.png)

.png)

.png)

.png)

.png)

.png)