WHAT ARE THE ADVANTAGES OF A TUBELESS TIRE?

IS TUBELESS FOR EVERYONE?

WHAT DO YOU NEED FOR TUBELESS FITTING?

- Schwalbe tubeless tires

- Airtight tubeless wheel

- (or tubeless-ready wheel and tubeless rim tape)

- Tubeless valve

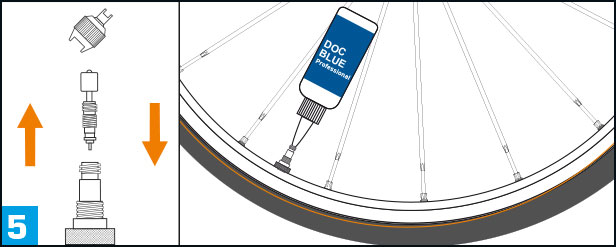

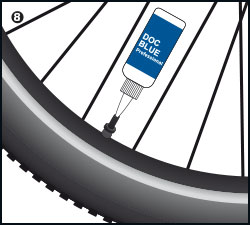

- Sealing liquid (e.g. Schwalbe Doc Blue)

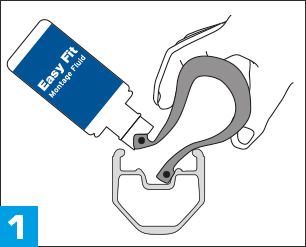

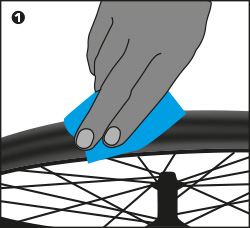

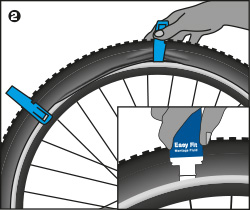

- Mounting fluid (e.g. Schwalbe Easy Fit)

- Track pump with air gauge

- A rag

HOW MUCH SEALING MILK DO I HAVE TO FILL IN?

Tires from 23-60 mm -> 60-90 ml/tire.

Tires from 62 -100 mm -> 90 -120 ml/tire.

Shake well! The sealing milk works up to 7 months.

Not suitable for coarse defects (cuts / punctures).

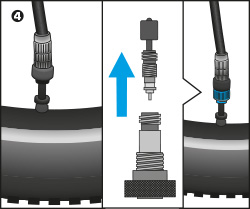

DO I HAVE TO INSERT THE SEALANT THROUGH THE VALVE?

WHY DO I NEED SEALANT?

Tubeless Easy tires are not completely airtight tubeless tires. You need the sealant to guarantee they are airtight. A sealant can do this more effectively than an impermeable butyl liner.

HOW FREQUENTLY DO I HAVE TO REFILL OR REPLACE THE SEALING LIQUID?

Doc Blue remains active as a puncture preventative for approx. 2000 km or 2-7 months. The period depends a lot of the temperature. After this time the sealant dries into a rubber film or separates into individual components („latex coral“ and liquid)..

WHAT TO DO, IF THE TIRE DOES NOT INFLATE?

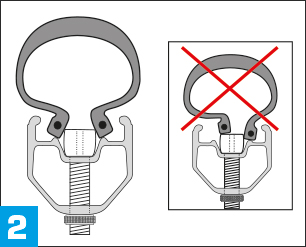

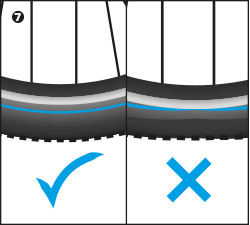

- Check, that the valve is positioned between the tire beads, blowing air into the tire.

- Use Mounting Fluid. Lubricating helps the tire beads to slide into the correct position more easily. In an emergency soapy water might also do the trick.

- Remove the valve core for increased air flow.

- When the tire seat is too loose, an additional layer of rim tape is frequently helpful to slightly increase the rim diameter.

- If the tubeless rim tape is old, defect or has extreme dimples at the spoke holes, replace with new tubeless rim tape.

- First, mount the tire with a tube and let sit for 24 hours to help stretch out the bead to the proper shape.

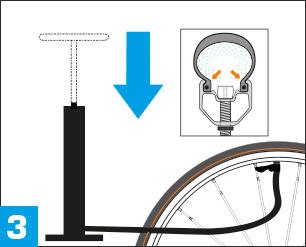

- In very stubborn cases, use a compressor or the Schwalbe Tire Booster.

WHAT ELSE CAN GO WRONG?

Leaks can of course also happen at the valve or the rim. In order to find them, you have to put the complete wheel under water or if you do not have a tank large enough to submerge the complete wheel, spray the wheel with soapy water. If there are leaks, air will emit at the valve and/or spoke nipples. This may take a while, because the pressure has to build up in the rim cavity first. Frequently, the valve area is the problem. Possible remedy: Tighten the valve nut, clean and trim the contact area, replace valve or replace the tubeless rim tape. If all this does not help, there might be a defect at the rim joint or a crack in the rim base.

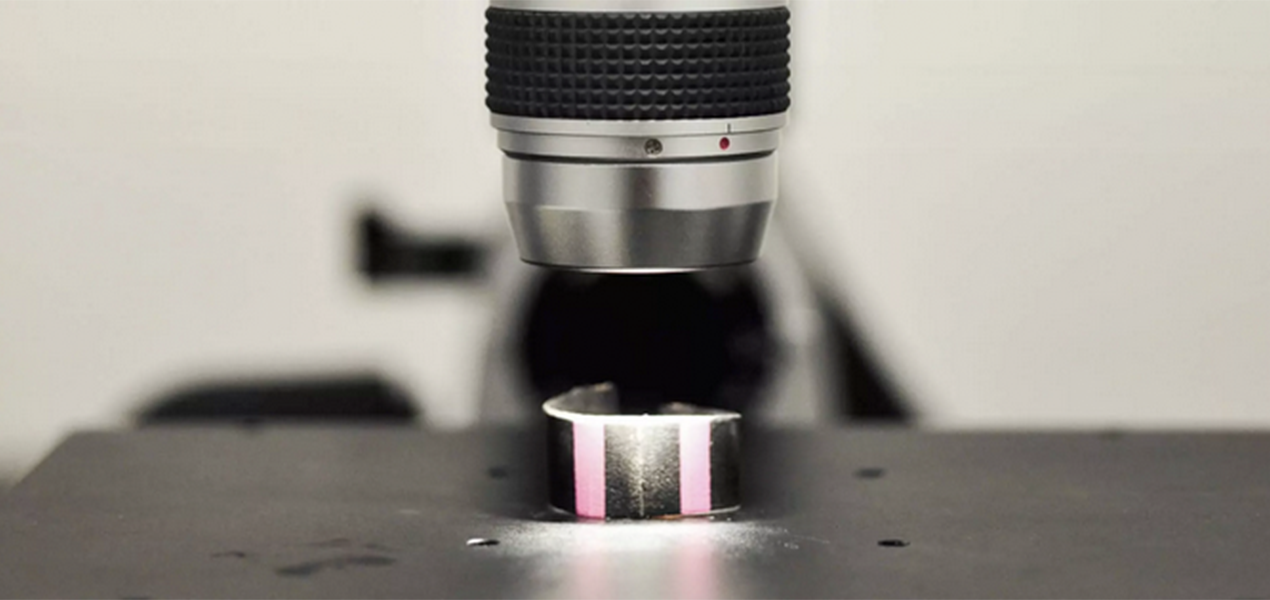

WHAT IS A TIRE BOOSTER?

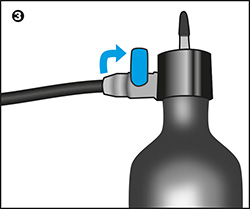

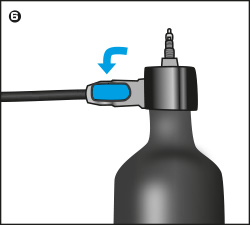

HOW TO USE THE TIRE BOOSTER?

- Do not exceed the maximum air pressure for the tire and rim.

- Do not exceed the maximum air pressure for the Tire Booster: 11 Bar/160 PSI.

- Never inflate the bottle with a compressor.

- Do not use a defective bottle, tire or rim.

- Do not release pressurized air into eyes or face.

- Before opening the ‘Air valve’: ensure pump head is attached securely to the valve of your wheel.

- Protect the bottle from direct sunlight. Avoid temperatures of below -15°C (5*F) and above +50°C (120*F).

- Store Tire Booster only with ‘Air Valve’ open.

WHICH WHEELS ARE SUITABLE FOR TUBELESS?

WHAT SHOULD I KNOW ABOUT RIM TAPE AND VALVE?

HOW TO HANDLE A FLAT?

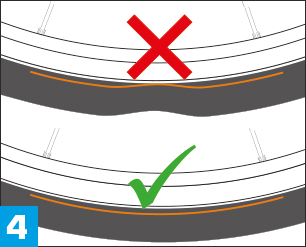

Punctures are automatically sealed and repaired by Doc Blue during the ride. Important: Keep riding or press the punctured part to the ground. Flexing supports the function of the sealant. Do not hold the defect spot to the top.