WHAT IS A BICYCLE TUBE MADE OF?

A bicycle tube is predominantly made of Butyl rubber. Butyl rubber. Butyl is a very elastic and airtight synthetic rubber. But as with the tire, other fillers are necessary to make up the rubber compound. The quality of a tube can vary significantly depending on the rubber compound. For instance Schwalbe tubes have extremely high air retention and elasticity. This high elasticity allows a wide range of different tire sizes to be covered.

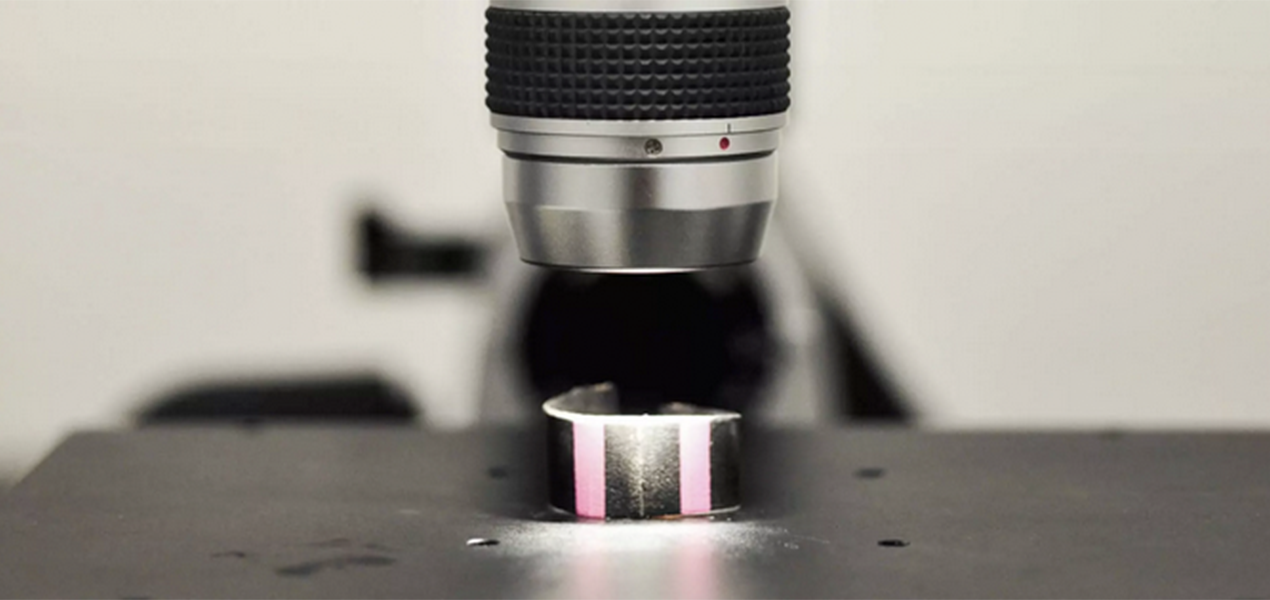

There is a difference between heat molded and autoclave tubes. Vulcanizing in a mold improves the uniformity of wall thickness, thus reducing weight and improving air retention. For this reason the autoclave tubes which can be produced easier have become less common over the past years. Schwalbe tubes have always been made using the heat molding process.

Every tube also needs a valve, which is bonded to the tube during the vulcanizing process.

WHICH SPECIAL FEATURES DOES A SCHWALBE TUBE OFFER?

Besides the quality of the ingredients, the purity of the rubber compound is decisive for the quality of the tube. Before extrusion, the basic material is forced through a total of seven filters under enormous pressure. All tubes are inserted and inflated into a mold for the vulcanization process. Only this ensures an even wall thickness and high air retention.

All tubes are inflated and stored for 24 hours to test for air retention. Afterwards, every tube is carefully checked individually by visual inspection. The Schwalbe tube has been valued by German bicycle dealers for its high reliability for many years.

A tube covers many tire sizes through its high elasticity and quality. Tube no. 17 works with tires from a width of 28 mm up to 47 mm - a great advantage for stockholding in the trade. At the same time, it is proof of the quality of the tube.

All valves are nickel-plated and threaded. The valve core is always replaceable. Also, Schwalbe tubes with a classic bicycle valve can be inspected for pressure as they have a high-pressure valve core.

Every Schwalbe tube is 100% recyclable. Without any loss of quality we can use recycled material in the production of new tubes. We have developed in our own factory a special devulcanization process and for several years, it has proved very successful. Right now every Schwalbe standard tube is made up of 20% recycled old tubes.

Taking into account all transport routes, the energy balance is positive. Just a fifth of the energy is used in comparison with the production of new butyl.

In Germany, we support the return process of old bicycle inner tubes with a collection process that bicycle dealers can easily participate in and that is free of charge.

WHAT ARE THE ADVANTAGES OF LATEX TUBES?

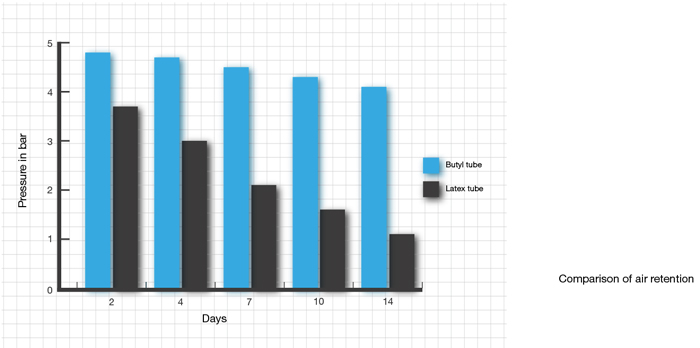

Tubes made out of latex are more elastic than normal butyl tubes. This makes them roll a little more easily. Their greatest advantage lies in the high level of puncture protection. The highly elastic latex material is very difficult to puncture.

The disadvantage lies in poor air retention. A tire with a latex tube must be adjusted for inflation pressure before every trip. This explains why latex tubes are not well suited for everyday use..

In addition, latex tubes are very delicate and susceptible , to oil, daylight, heat and uneven expansion. The tube must also be replaced every time a tire is changed. Because these sensitivities lead to many problems in the field, we do not offer latex tubes.