WHAT EXACTLY IS ROLLING RESISTANCE?

Rolling resistance is the energy that is lost when the tire is rolling. The main reason for the loss of energy is the constant deformation of the tire.

Each bicycle tire should, of course, roll as easily as possible. In contrast to a car a cyclist has only (very limited) physical power which he wants to apply as efficiently as possible.

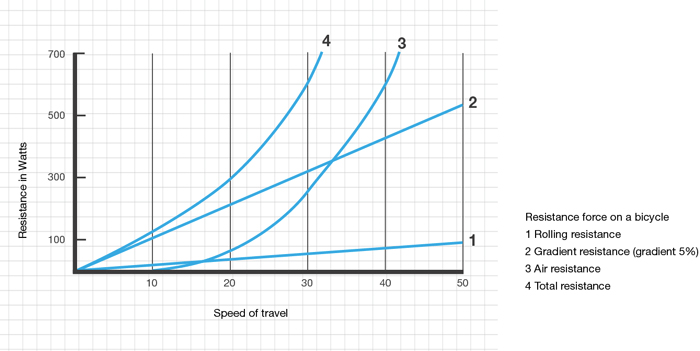

The air resistance rises in a squared ratio with increased speed. At a speed of approx. 20 km/h on level ground, air resistance has already become the main resistance force.

Acceleration energy is also expended. For instance, the weight of the wheels is of great importance when this mass has to be brought up to rotation.

When riding uphill, the main resistance force to be overcome is the gradient resistance (grade resistance).

In addition to these, there are other friction resistances in the chain and in other rotating parts. Yet in a well-serviced bicycle, these represent a very minor part of the total resistance.

WHICH FACTORS AFFECT ROLLING RESISTANCE?

Tire pressure, tire diameter, tire width, tire construction, tire tread and other factors all have an effect on rolling resistance.

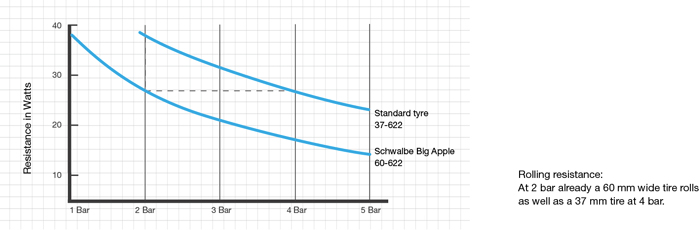

On a completely smooth surface the following applies: The higher the inflation pressure, the inferior the tire deformation and thus rolling resistance.

Off road it is exactly the reverse: The lower the inflation pressure, the lower the rolling resistance. This applies equally on hard gravel roads and soft forest tracks. Explanation: A tire with low inflation pressure can adapt better to a rugged surface. It sinks into the ground less and the whole rotational mass is held back much less by the uneven surface.

Tires with a smaller diameter have a higher rolling resistance with the same inflation pressure, because tire deformation is proportionally greater. The tire is flattened more and is “less round”.

Wider tires roll better than narrower tires. This statement generally invokes skepticism, nevertheless, with tires at the same pressure a narrower tire deflects more and so deforms more.

Obviously, tire construction also has an effect on rolling resistance. By using less material, less material can be deformed. And the more flexible the material is, such as the rubber compound, the less energy is lost through deformation.

Generally, smooth treads roll better than coarse treads. Tall lugs and wide gaps usually have a detrimental effect on rolling resistance.

WHY DO WIDE TIRES ROLL BETTER THAN NARROWER TIRES?

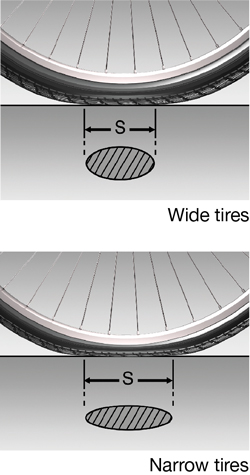

The answer to this question lies in tire deflection. Each tire is flattened a little under load. This creates a flat contact area.

At the same inflation pressure, a wide and a narrow tire have the same contact area. A wide tire is flattened over its width whereas a narrow tire has a slimmer but longer contact area.

The flattened area can be considered detrimental to tire rotation. Because of the longer flattened area of the narrow tire, the wheel loses more of its “roundness” and produces more deformation during the rotation. In a wide tire, the flattened area is shorter in length and does not have so much effect on the rolling direction. The tire stays “rounder” and therefore it rolls better.

WHY DO PROFESSIONAL ROAD RACERS USE NARROW TIRES?